Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

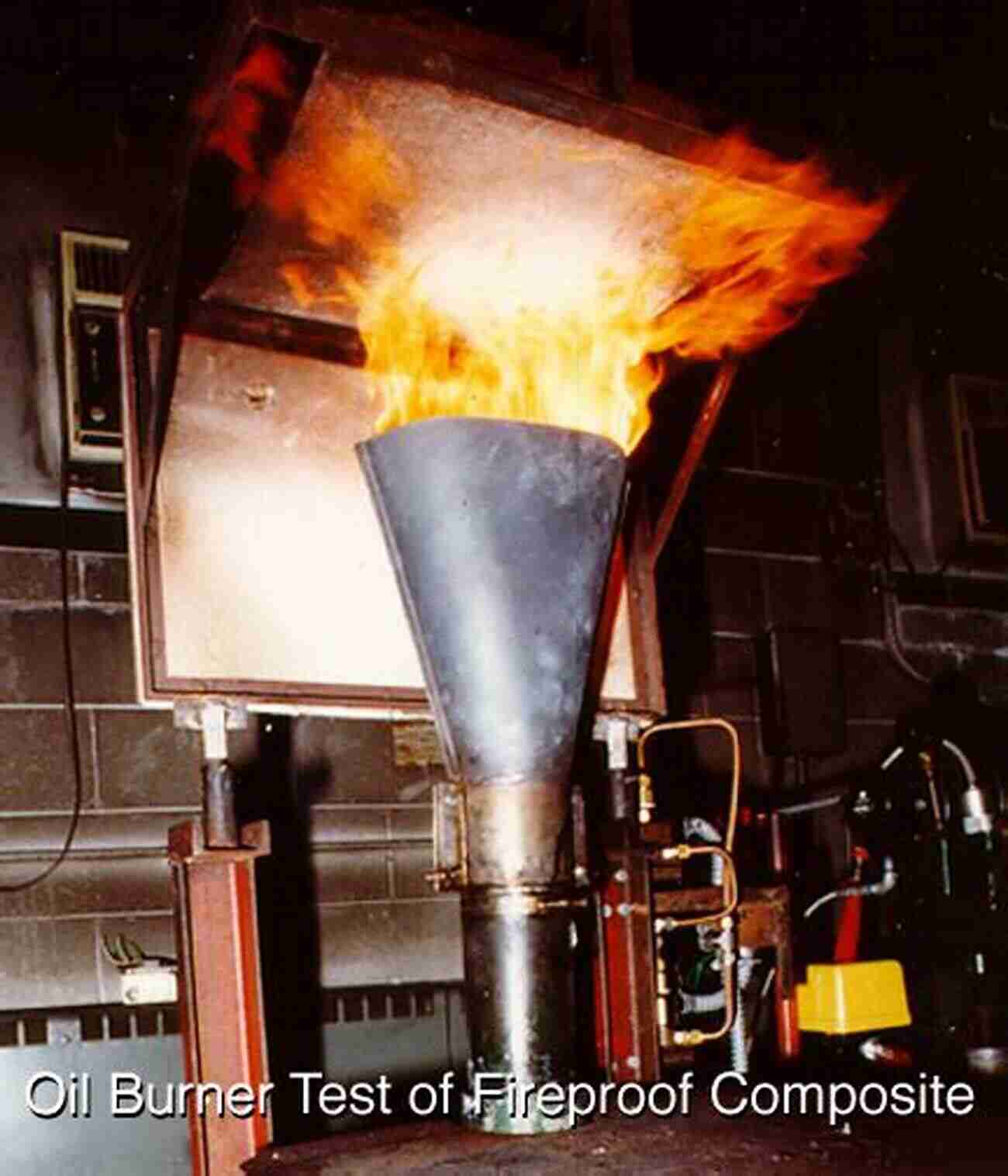

Understanding the Flammability, Smoke, and Combustion Toxicity Requirements for Composites Plastics

Composite plastics have revolutionized industries with their lightweight properties and high strength-to-weight ratio. They are extensively used in aerospace, automotive, marine, and other applications where weight reduction is critical. However, ensuring the safety of composite plastics in case of fire is crucial, as they can contribute to the spread of fire and release toxic gases.

What are Flammability, Smoke, and Combustion Toxicity Requirements?

Flammability, smoke, and combustion toxicity requirements are essential standards used to evaluate the fire performance of composite plastics. These requirements ensure that composite plastics used in critical applications meet specific safety standards. The evaluation involves understanding how the materials react when subjected to heat, flame, and other fire hazards.

Flammability Requirements for Composite Plastics

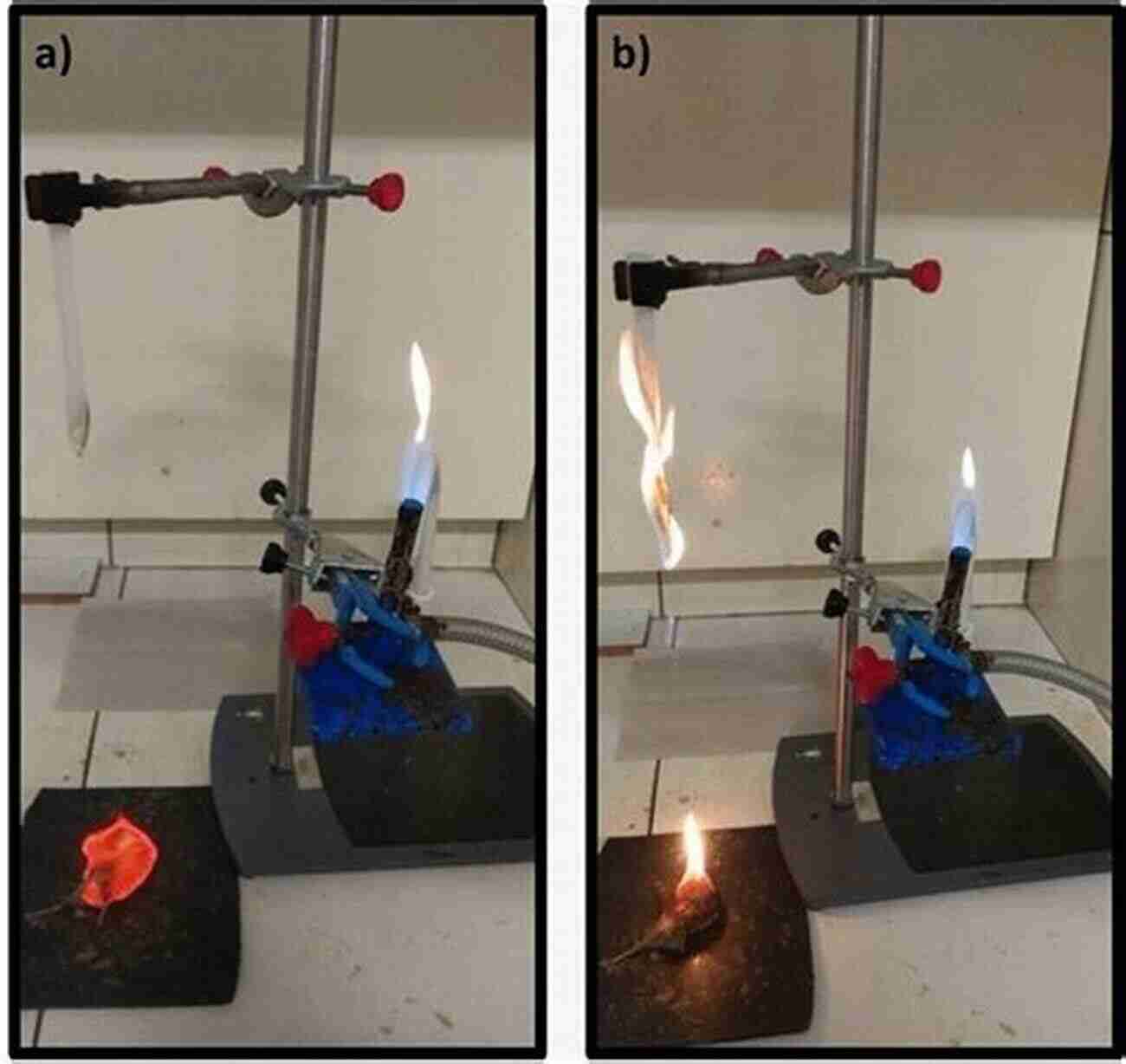

Flammability testing determines the ignition and burning behavior of composite plastics. The tests determine the ability of the material to propagate flame and the rate at which it burns. Flammability requirements aim to limit the potential spread of fire and reduce the severity of fire hazards.

4 out of 5

| Language | : | English |

| File size | : | 16008 KB |

| Screen Reader | : | Supported |

| Print length | : | 202 pages |

[Descriptive keyword: Composite Plastic Flammability]

Commonly used flammability testing standards for composite plastics include ASTM E84, UL 94, FAR 25.853, and ISO 5660. These standards involve subjecting the material to an open flame, evaluating its burning behavior, and measuring parameters such as flame spread, heat release rate, and smoke production.

Smoke Requirements for Composite Plastics

Smoke production is a critical aspect of fire safety, as dense smoke can limit visibility and hinder evacuation. The smoke generated during a fire may contain toxic gases, making it even more dangerous. Smoke requirements for composite plastics aim to limit the amount of smoke generated and its toxicity level.

[Descriptive keyword: Composite Plastic Smoke Production]

Smoke testing involves measuring the smoke density and/or optical density during controlled combustions. Standards such as ASTM E662, ISO 5659, and ASTM E2067 provide guidelines for conducting smoke tests on composite plastics. The results from these tests determine the smoke performance of the materials, allowing manufacturers to select or modify materials that meet the required safety standards.

Combustion Toxicity Requirements for Composite Plastics

Combustion toxicity requirements assess the potential health risks associated with the toxic gases and fumes released by burning composite plastics. When exposed to fire, composite plastics can release toxic gases such as carbon monoxide, hydrogen cyanide, and various other combustion by-products.

[Descriptive keyword: Composite Plastic Combustion Toxicity]

Standards like NFPA 130 and EN 45545-2 specify the tests and criteria for evaluating the combustion toxicity of materials used in railways. These tests simulate real fire conditions and measure parameters like smoke toxicity, acid gas emission, and heat release rate. Compliance with these standards ensures the materials used in railway applications do not pose excessive risks to passengers in case of fire.

Ensuring Compliance with Flammability, Smoke, and Combustion Toxicity Requirements

To ensure compliance with the flammability, smoke, and combustion toxicity requirements for composite plastics, manufacturers must conduct rigorous testing and analysis. Materials that fail to meet the specified standards may need to be modified or replaced with alternative materials that meet the required safety standards.

[Descriptive keyword: Composite Plastics Safety Standards]

It is essential for manufacturers to work closely with testing laboratories and fire safety experts to design and develop composite plastics that comply with the necessary regulations. This involves conducting thorough material characterization, research, and testing, ensuring the materials exhibit desired fire-resistant properties.

The flammability, smoke, and combustion toxicity requirements play a vital role in enhancing the fire safety of composite plastics used in various industries. Adhering to these requirements ensures that composite plastics meet the necessary safety standards, limiting the spread of fire, reducing smoke production, and minimizing the risks associated with combustion toxicity.

Manufacturers and industry experts must remain updated with the latest standards and regulations to ensure the use of safe composite plastics in critical applications.

4 out of 5

| Language | : | English |

| File size | : | 16008 KB |

| Screen Reader | : | Supported |

| Print length | : | 202 pages |

A must for suppliers of materials who want to enter this continually growing market. "Flammability, Smoke, and Combustion Toxicity Requirements for Composites, Plastics, Textiles, and Other Materials Used In: Planes, Trains, Buses, and Cruise Ships" presents a wealth of information that relates to the required: Flammability, Smoke, & Combustion toxicity tests.It describes the products to be tested along with pass/fail criteria.The book’s illustrations and summaries give the reader outstanding reference points to measure the potential of their products to comply.All key modes of public transportation are analyzed.Air Craft IndustryFAA Federal Aviation Administration (US)BSS Boeing specification support standardAITM Airbus Industries Test MethodRail Passenger Cars (United States)FRA Federal Railroad AdministrationNFPA 130 National Fire Protection AssociationIMO 2010 International Maritime OrganizationBusses and VansDocket 90-A Federal Transit Administration (US)Just some of the many tests that are included with pass/fail criteria.Includes, combustion toxicity, smoke density, surface flame spread, rate of heat release, insulation burnthrough, vertical burn measurements, and many others.

Harrison Blair

Harrison BlairSoldiers League: The Story of Army Rugby League

The Origin and History The Soldiers...

Bob Cooper

Bob CooperFilm Quiz Francesco - Test Your Movie Knowledge!

Are you a true movie buff? Do you...

Hugh Reed

Hugh ReedDriving Consumer Engagement In Social Media

: Social media has...

Richard Simmons

Richard SimmonsAll You Need To Know About The Pacific Ocean Ocean For...

The Pacific Ocean is the largest ocean in...

Carson Blair

Carson BlairUnveiling the Intriguing World of Complex Wave Dynamics...

The study of complex wave...

Connor Mitchell

Connor MitchellUnraveling the Mysterious Journey of "The Nurse And The...

Once upon a time, in a world of endless...

Colt Simmons

Colt SimmonsHow To Change Your Child's Attitude and Behavior in Days

Parenting can be both challenging and...

Reginald Cox

Reginald Cox10 Groundbreaking Contributions Through Science And...

Science and technology have always...

Ernesto Sabato

Ernesto SabatoUnleashing the Power of Hamilton Education Guides Manual...

Are you struggling with understanding...

Virginia Woolf

Virginia WoolfThe Astonishing Tale of Mars: Lord of the Dragon Throne -...

There has always been a remarkable...

Colt Simmons

Colt SimmonsAn Introduction For Scientists And Engineers Second...

Are you a budding scientist or engineer...

Howard Blair

Howard BlairDiscover the Coolest and Trendiest Friendship Bracelets -...

Friendship bracelets have...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Vincent MitchellDiscover the Breathtaking Beauty of Paddleboarding in England, Scotland, and...

Vincent MitchellDiscover the Breathtaking Beauty of Paddleboarding in England, Scotland, and... Rick NelsonFollow ·5k

Rick NelsonFollow ·5k Gregory WoodsFollow ·4.3k

Gregory WoodsFollow ·4.3k Eugene PowellFollow ·13.3k

Eugene PowellFollow ·13.3k Rodney ParkerFollow ·16k

Rodney ParkerFollow ·16k Thomas MannFollow ·19.8k

Thomas MannFollow ·19.8k Blake BellFollow ·4.7k

Blake BellFollow ·4.7k W. Somerset MaughamFollow ·15.7k

W. Somerset MaughamFollow ·15.7k Braden WardFollow ·14.6k

Braden WardFollow ·14.6k